PRODUCT CATEGORIES

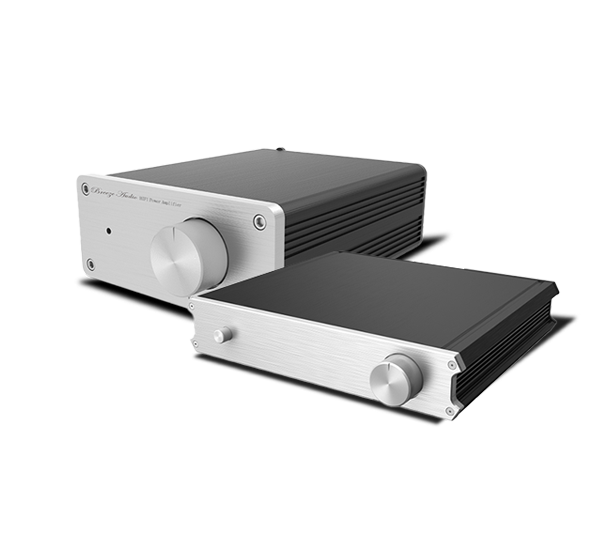

BRZHIFI Aluminum Alloy Chassis

Provide high-quality and innovative all-aluminum chassis products to meet the diverse needs of our customers.

LATEST PRODUCT

Featured Collection

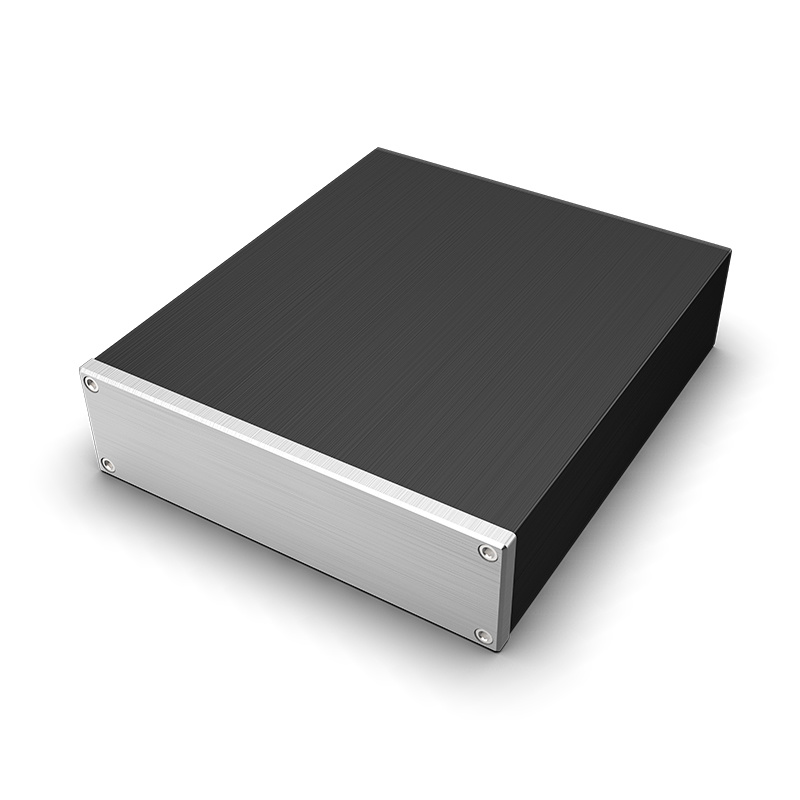

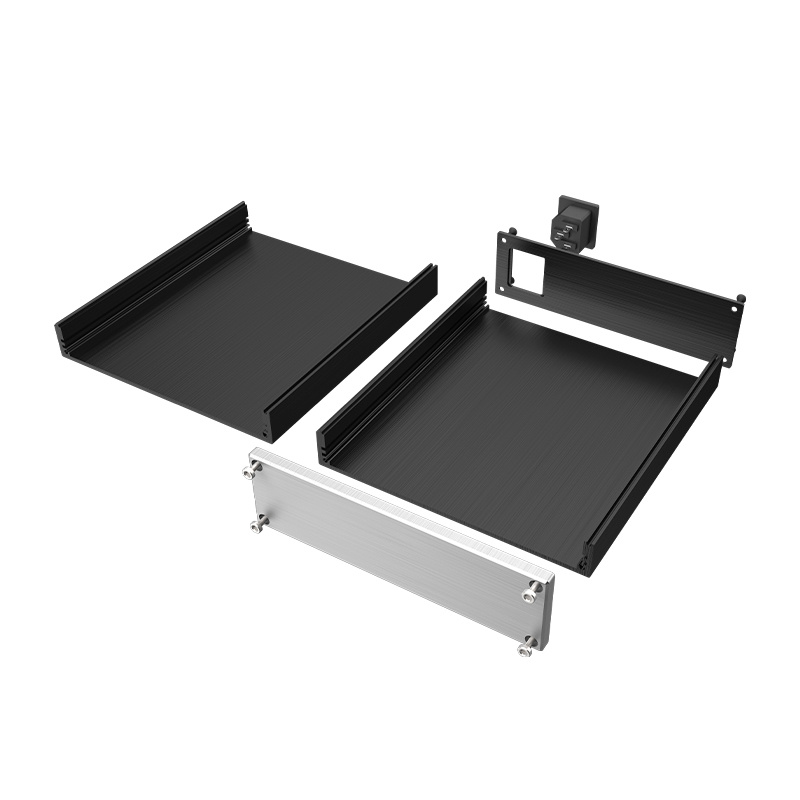

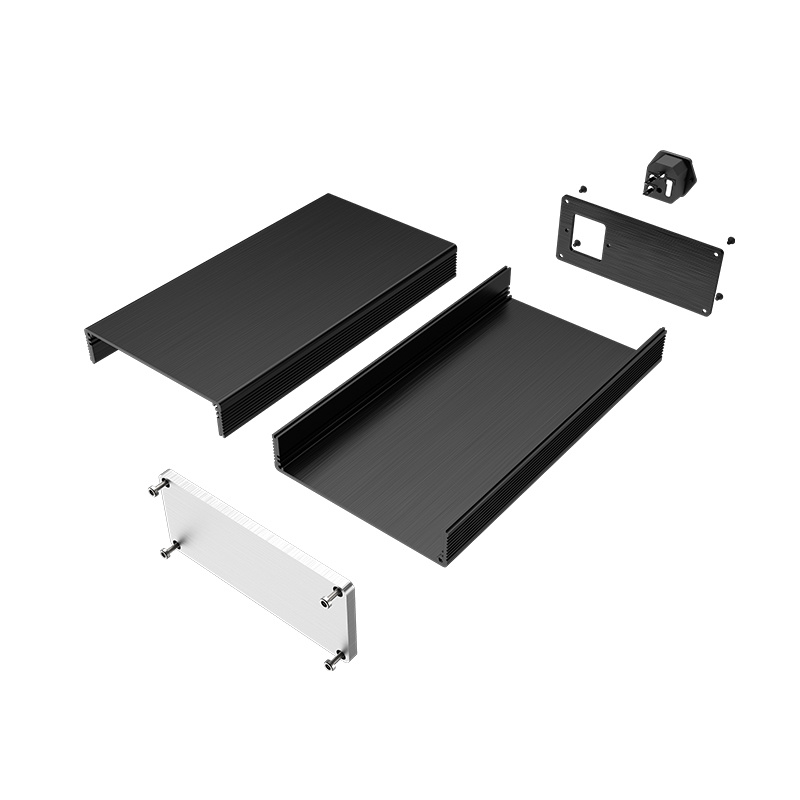

U-Shaped Buckle Enclosure

Aluminum alloy preamp earphone amplifier DAC enclosure

U-Shaped Buckle Enclosure

All-aluminum blank mini-chassis suitable for pre-amplifiers and headphone amplifiers.

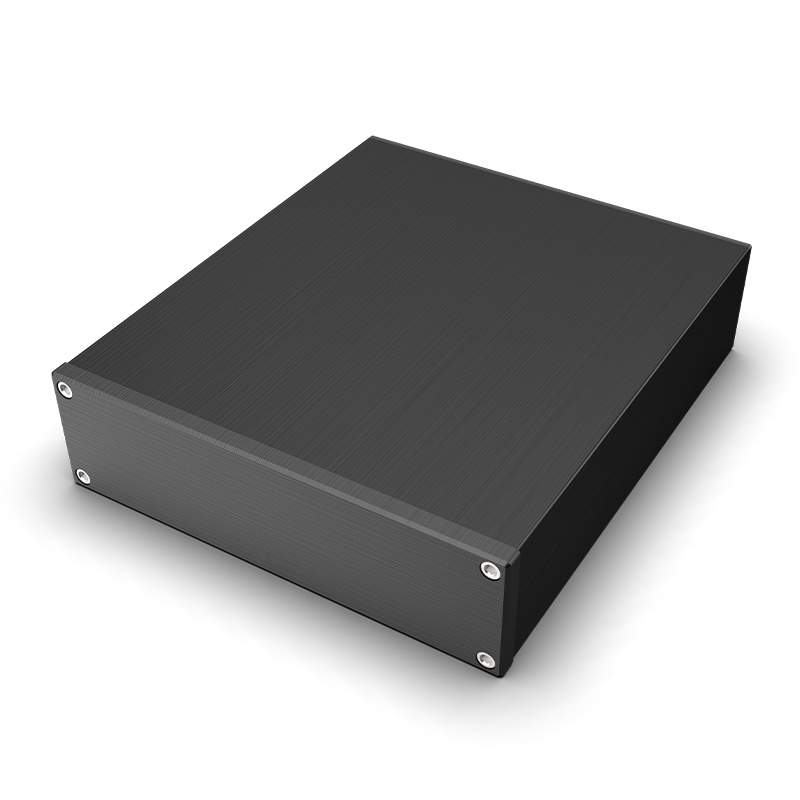

U-Shaped Buckle Enclosure

Mini amplifier, pre-amplifier enclosures, multiple sizes.

U-Shaped Buckle Enclosure

Suitable for small split power supply, headphone amplifier, linear power supply enclosures.

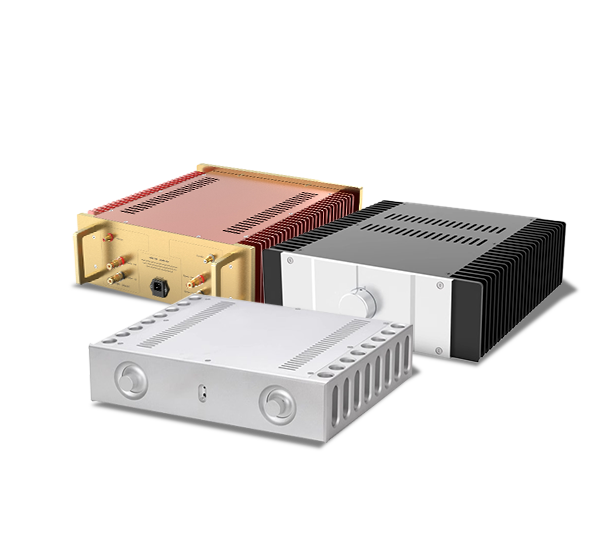

Profile splicing aluminum enclosure

Amplifier: Preamp/tube amp/power supply Instrumentation and industrial control equipment: Medical box, industrial control box, computer box, set-top box

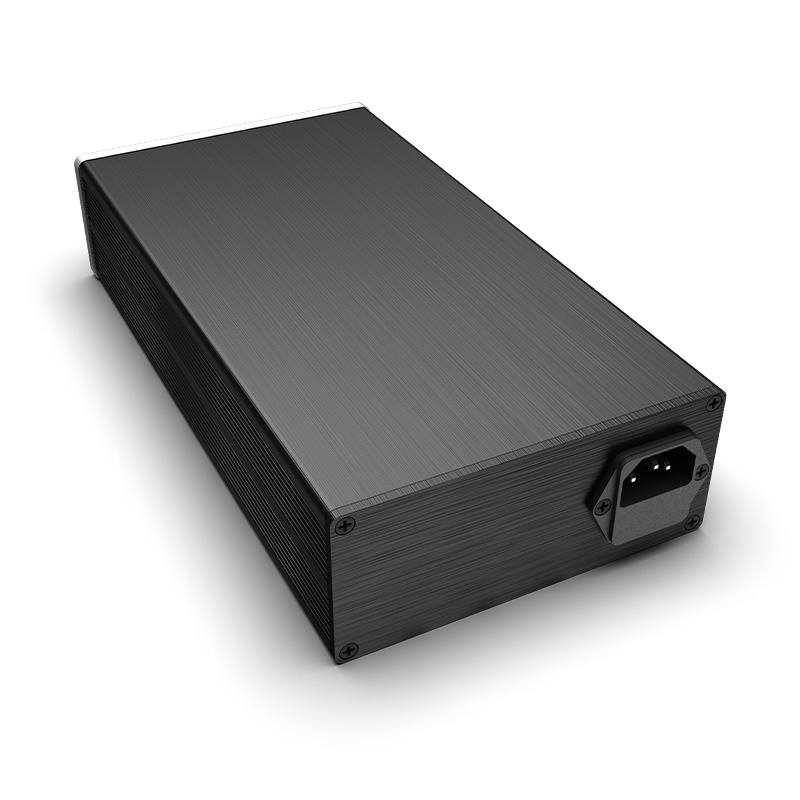

Power Supply Enclosure

Electronic isolation box with digital meter, power supply box

Speaker Enclosure

Home Mini 2.5-inch Desktop Full Aluminum Speaker Enclosure

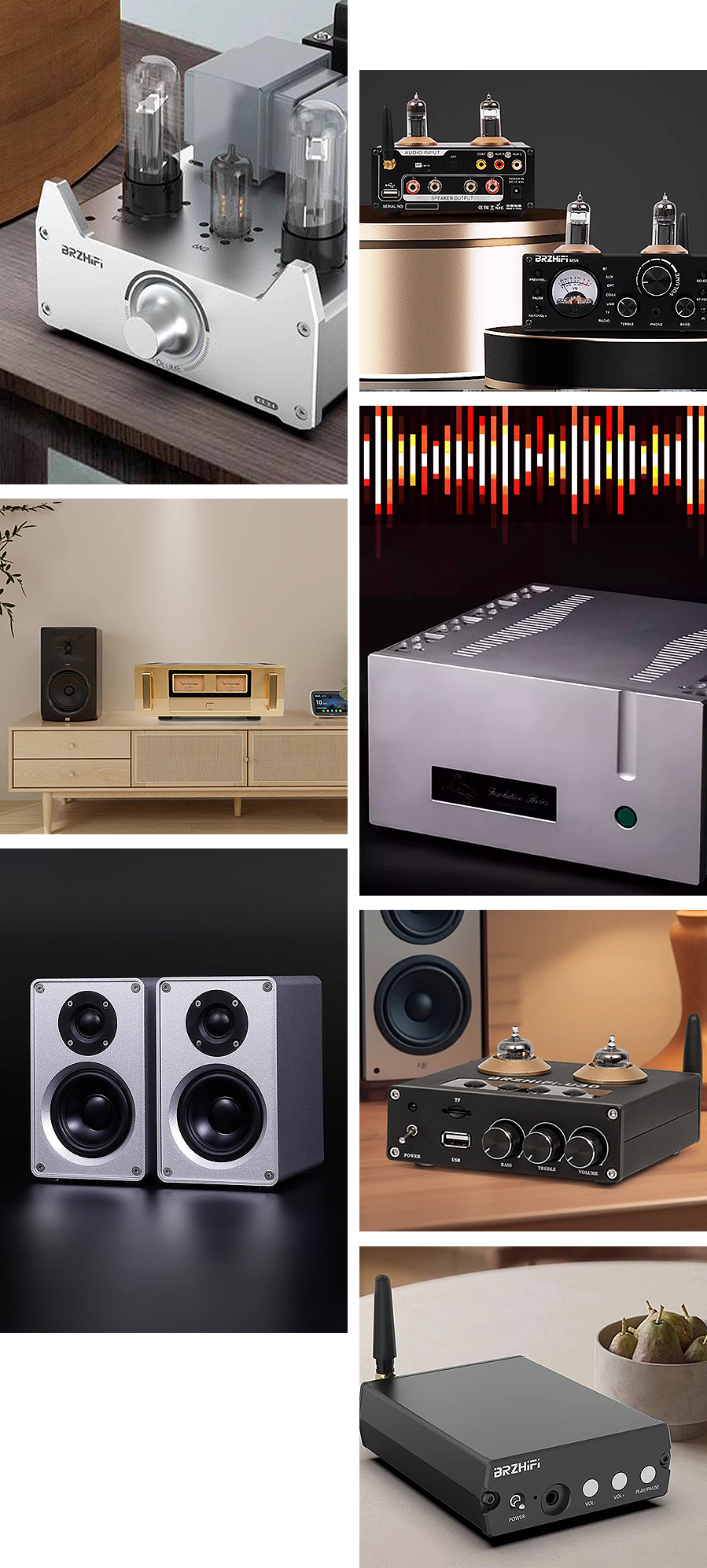

Service Covers Multiple Fields

Power Amplifiers

Instrumentation

Headphone Amplifiers

Tube Amplifiers

Soldering Stations

CD Players

Power Supplies

Industrial Control Enclosures

BRZHIFI

Customized Service

Source Factory, Quality Assurance, Undertaking Batch customization

Collaborative Product Development

Our cross-functional development team integrates industrial aesthetics with engineering mechanics, with senior experts averaging over 12 years of experience in product development. By harnessing the collaborative efforts of industrial designers, mechanical engineers, and materials science specialists, we deliver comprehensive development packages that include 3D digital models, engineering drawings, vector branding files, and detailed material process specifications—ensuring a seamless transition from concept to mass production.

Intelligent Precision Machining

Equipped with more than 20 multi-axis machining centers and Swiss-grade precision inspection systems, we have established a flexible production system that covers everything from rapid prototyping to high-volume manufacturing. Our modular process design enables both single-piece trial production and mass production on the scale of tens of thousands of units simultaneously. Digital process control guarantees machining accuracy within ±0.01mm and stable consistency across batches.

Customized Surface Treatment

Utilizing an advanced anodizing composite process, we can elevate the surface hardness of aluminum alloy casings to above HV400, with corrosion resistance in salt spray tests exceeding 1,000 hours. We offer full-spectrum Pantone color customization along with differentiated surface finishes such as matte, glossy, and textured options, perfectly balancing functional protection with distinctive brand visual identity.

Diverse Marking Solutions

We provide six surface marking technologies, including laser engraving, pad printing, and UV digital printing. Our capabilities include micro-engraving with 0.1mm line width precision and four-color gradient pattern printing, ensuring an accurate reproduction of corporate VI elements. Through multi-layer coating technology, our markings remain clear for over ten years even in harsh environments, meeting rigorous industrial durability standards.

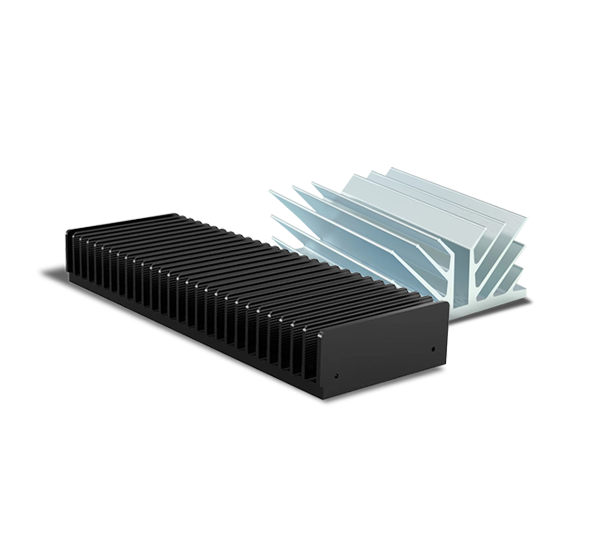

Various aluminum materials available for selection

We can provide the most suitable aluminum material types for your products, ensuring both quality and performance requirements.

What Sets BRZHIFI Apart From Other Manufacturers?

Since its establishment in 2014, the company has been dedicated to the production of all-aluminum chassis and brackets.

Get In TouchExpert Customization & Secure Production

Our dedicated design team (15+ years of experience) provides tailored solutions based on your 3D/CAD/CDR files or sketches. Every project is managed by engineers with over a decade of expertise, ensuring strict confidentiality in design and production.

Premium Materials & Precision Manufacturing

We use 99% high-purity aluminum for superior strength and corrosion resistance. Equipped with 86 advanced machines (CNC, laser cutting, etc.) and a 4,000㎡ workshop, we guarantee machining tolerances within 0.1 mm.

Scalable Infrastructure & Storage Capacity

Our 4,000㎡ production facility and matching warehouse space enable large-scale operations, storing 10,000+ parts and 1,000+ finished products to meet urgent or bulk orders efficiently.

Rigorous Quality Control & Reliability

Every product undergoes 100% inspection by our QC team, ensuring 100% compliance with standards. We maintain a 98% on-time delivery rate, combining speed with uncompromised quality.

ABOUT BRZHIFI

Professional Aluminum Chassis Manufacturer

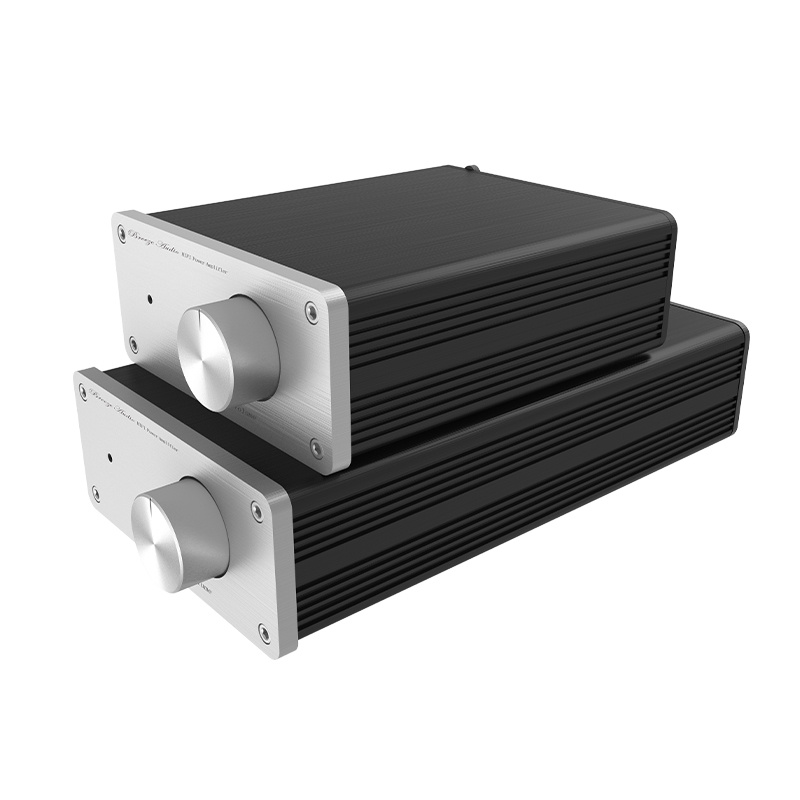

We are a comprehensive enterprise integrating R&D, design, production and sales, focusing on the manufacturing of aluminum enclosures for audio products and other electronic industrial control. Our new trademark is BRZHIFI (former Breeze audio, Weiliang audio)

Our aim is to produce high quality aluminum enclosures to spread the best quality for electronic products, to provide good solutions for your amplifiers, power supplies, radios, speakers and CD players enclosures, and to provide good service to all customers.

After more than 16 years of development, the production workshop has advanced CNC, large milling machine and laser cutting machine. We have enough raw materials and production workers to serve big orders. We have our own machining team, company R&D staff to meet your diverse designs and needs.

Founded in

Number of global export countries

Total area of the company and partners' facilities

Current number of employees

Number of production lines

Professional collaboration departments

2025-03-05

Adapting Transformer Cases for Multifaceted Scenario Needs

The requirements for transformer cases differ according to various application scenarios.

Send Inouiry Online2025-03-05

Technological Innovations Enhance Performance and Adaptability

The use of advanced materials, optimized ventilation and cooling systems, improved electrical safety features, integration of smart functions, and a focus on environmental friendliness are the main innovation aspects. These advancements enhance the performance and reliability of transformers and make them more adaptable to the development of the power industry.

Send Inouiry Online2025-03-05

Transformers and Safety: Protecting Your Power Equipment

The transformer case is a key component in power systems. Made from quality materials, it provides physical protection against external factors, ensures electrical insulation, manages heat, and offers maintenance - friendly features.

Send Inouiry Online