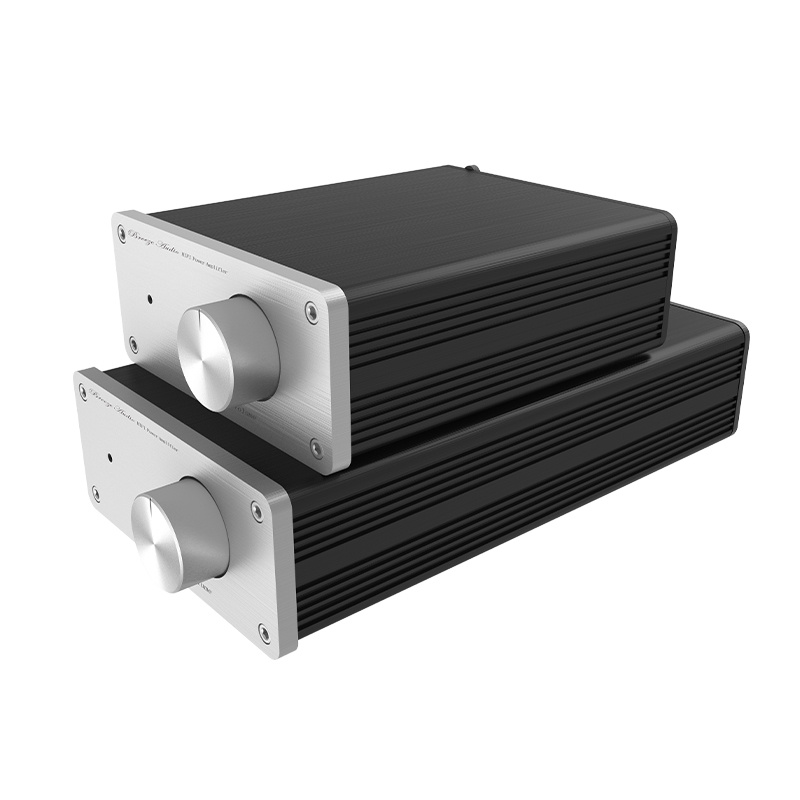

230-160 All-in-One Box

Number: AO-HY-230x160

Name: 230-160 All-in-One Box

Weight: 13.85kg/m

Aluminum Profile Model: 6063

Dimensions: 230mmx160mm

Length (Maximum available length): 2.2m

If you need customized products, Contact US !

Tag list: 230-160 All-in-One Box

Product Description

In the aluminum market, 6061 and 6063 are two common aluminum alloy models. Although they all belong to the aluminum, but in the chemical composition, mechanical properties and application areas there are significant differences.

一、the difference in chemical composition

The main components of 6061 aluminum alloy are magnesium and silicon, of which the magnesium content is higher, which makes it has good strength and hardness. While 6063 aluminum alloy is manganese and silicon as the main alloying elements, manganese content is relatively high, giving it excellent plasticity and processing performance. The difference of these two alloying elements leads to their different performance in mechanical properties.

二、mechanical properties comparison

Due to the high magnesium content of 6061 aluminum alloy, its strength and hardness is relatively high, suitable for the need to carry high load occasions. In contrast, the plasticity and processing performance of 6063 aluminum alloy is more excellent, which can easily achieve the ideal precision requirements. In addition, in terms of tensile strength and yield strength, 6063 aluminum alloy also shows better fracture toughness.

三、Application Differences

Based on the chemical composition and mechanical properties of the above characteristics, 6061 and 6063 aluminum in the field of application is also different. 6061 aluminum alloy because of its high strength and hardness, often used in aerospace, automotive manufacturing and other high-end areas to withstand the complex mechanics of the environment and harsh conditions of use. On the other hand, 6063 aluminum alloy is widely used in construction materials, rail transportation, industrial parts and other fields, with its good plasticity and processing performance, to meet the manufacturing needs of various complex shapes and structures.

All in all, the significant differences in chemical composition, mechanical properties, and application fields between 6061 and 6063 aluminum materials, the selection of materials must closely align with the actual application environment and requirements. When projects require materials with high strength and hardness, 6061 aluminum is undoubtedly the ideal choice; on the other hand, if the pursuit is for superior ductility and workability, 6063 aluminum is more suitable. We fully utilize the unique properties of these two aluminum materials, carefully designing and manufacturing aluminum alloy shells that are both sturdy and aesthetically pleasing, meeting diverse application needs.

Previous Page

Next Page

Corporate Strengths Overview

Expert Customization & Secure Production

Our dedicated design team (15+ years of experience) provides tailored solutions based on your 3D/CAD/CDR files or sketches. Every project is managed by engineers with over a decade of expertise, ensuring strict confidentiality in design and production.

Premium Materials & Precision Manufacturing

We use 99% high-purity aluminum for superior strength and corrosion resistance. Equipped with 86 advanced machines (CNC, laser cutting, etc.) and a 4,000㎡ workshop, we guarantee machining tolerances within 0.1 mm.

Scalable Infrastructure & Storage Capacity

Our 4,000㎡ production facility and matching warehouse space enable large-scale operations, storing 10,000+ parts and 1,000+ finished products to meet urgent or bulk orders efficiently.

Rigorous Quality Control & Reliability

Every product undergoes 100% inspection by our QC team, ensuring 100% compliance with standards. We maintain a 98% on-time delivery rate, combining speed with uncompromised quality.

Qualification Certification

To explore the global market, we adhere to the principles of people-oriented, product quality oriented, integrity-based, service-oriented, and win-win cooperation. Looking forward to your participation!

Related Product

Aluminum alloy preamp earphone amplifier DAC enclosure

Blank panel aluminum amplifier shell

All-aluminum blank mini-chassis suitable for pre-amplifiers and headphone amplifiers.

Mini amplifier, pre-amplifier enclosures, multiple sizes.

Suitable for small split power supply, headphone amplifier, linear power supply enclosures.

Amplifier: Preamp/tube amp/power supply Instrumentation and industrial control equipment: Medical box, industrial control box, computer box, set-top box

Electronic isolation box with digital meter, power supply box

Home Mini 2.5-inch Desktop Full Aluminum Speaker Enclosure

Frequently Asked Questions

How to address accuracy loss in aluminum enclosure machining caused by equipment aging?

How to ensure production efficiency and quality control for large-volume orders?

How to choose between spray coating and anodized oxidation for aluminum enclosure surface treatment?

How to balance innovative design and production feasibility for customized complex aluminum enclosures?

How to select aluminum alloy materials to ensure stability and durability for audio product enclosures?