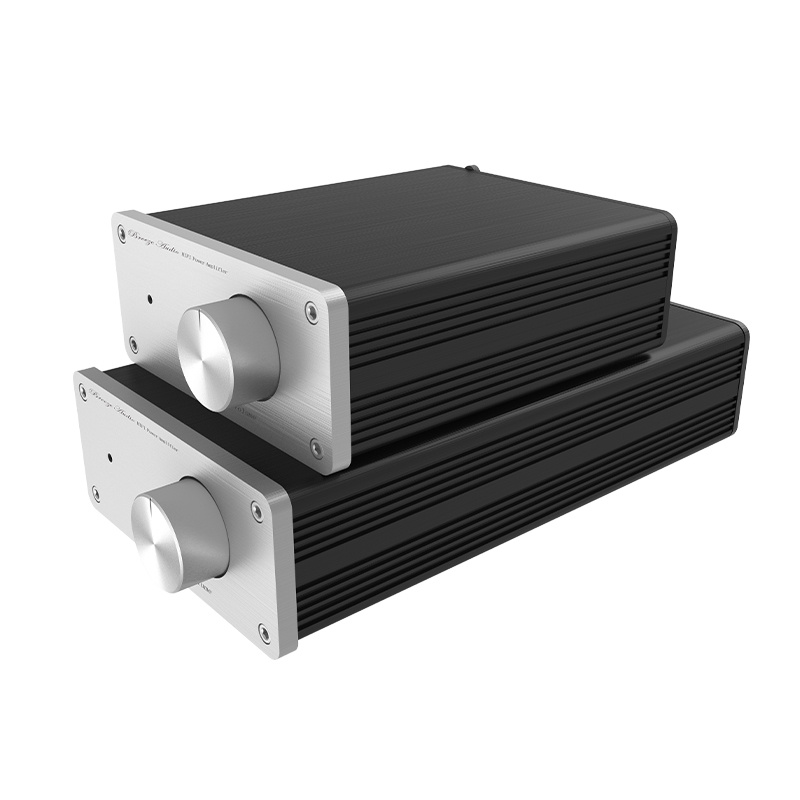

Y-shaped Heat Sink 3

All products can be customized:

Color: black, silver or other

Size: Customizable

Shape: Customizable

Perforation: customizable

Substrate thickness: customizable

Surface treatment process: customizable

If you need customized products, Contact US !

Tag list: Y-shaped Heat Sink 3

Category:

Product Description

The main function of the amplifier heat sink is to reduce the heat generated by the amplifier during the working process, to ensure its normal operation and extend its service life. The amplifier will generate a lot of heat when working, if not timely heat dissipation, high temperature may lead to equipment performance degradation or even damage. Therefore, an efficient heat dissipation system is one of the key aspects of amplifier design.

The Importance of Amplifier Heat Sinks

. Ensure the stable operation of the equipment: Efficient heat dissipation system can prevent the performance of the amplifier from deteriorating or being damaged due to overheating, and ensure the stable operation of the equipment for a long period of time.

. Extend the service life: good heat dissipation helps to reduce the aging of electronic components caused by high temperature, thus extending the service life of the amplifier.

. Enhance the sound quality: a stable temperature environment can ensure that the output power of the amplifier and the sound quality is maintained in the best state, to avoid the loss of sound quality caused by temperature fluctuations.

Design Requirements and Technical Challenges of Amplifier Heat Sinks

. Material selection: choose the right thermal conductive material: aluminum alloy to achieve the best heat dissipation effect, while considering the durability of the material.

. Structural design: Design the appropriate heat dissipation structure according to the specific requirements of the amplifier, including the shape and spacing of the fins as well as the overall dimensions, in order to maximize the heat exchange efficiency.

. Surface treatment: anodizing, painting and other protective treatments are applied to the heat sink to enhance appearance and durability.

. Production process innovation: more precise CNC machining and die-casting technology are used to improve production efficiency and product quality.

. Environmental Requirements: As environmental regulations become stricter, we are adopting greener solutions in material selection and waste disposal.

We focus on providing high-quality heat sinks, dedicated to meeting the diverse needs of our customers. Welcome customers to provide drawings for sampling, we will use exquisite craftsmanship and a rigorous attitude to create heat sink products that meet your requirements. Looking forward to cooperating with you to create a better future together!

Previous Page

Next Page

Corporate Strengths Overview

Expert Customization & Secure Production

Our dedicated design team (15+ years of experience) provides tailored solutions based on your 3D/CAD/CDR files or sketches. Every project is managed by engineers with over a decade of expertise, ensuring strict confidentiality in design and production.

Premium Materials & Precision Manufacturing

We use 99% high-purity aluminum for superior strength and corrosion resistance. Equipped with 86 advanced machines (CNC, laser cutting, etc.) and a 4,000㎡ workshop, we guarantee machining tolerances within 0.1 mm.

Scalable Infrastructure & Storage Capacity

Our 4,000㎡ production facility and matching warehouse space enable large-scale operations, storing 10,000+ parts and 1,000+ finished products to meet urgent or bulk orders efficiently.

Rigorous Quality Control & Reliability

Every product undergoes 100% inspection by our QC team, ensuring 100% compliance with standards. We maintain a 98% on-time delivery rate, combining speed with uncompromised quality.

Qualification Certification

To explore the global market, we adhere to the principles of people-oriented, product quality oriented, integrity-based, service-oriented, and win-win cooperation. Looking forward to your participation!

Related Product

Aluminum alloy preamp earphone amplifier DAC enclosure

Blank panel aluminum amplifier shell

All-aluminum blank mini-chassis suitable for pre-amplifiers and headphone amplifiers.

Mini amplifier, pre-amplifier enclosures, multiple sizes.

Suitable for small split power supply, headphone amplifier, linear power supply enclosures.

Amplifier: Preamp/tube amp/power supply Instrumentation and industrial control equipment: Medical box, industrial control box, computer box, set-top box

Electronic isolation box with digital meter, power supply box

Home Mini 2.5-inch Desktop Full Aluminum Speaker Enclosure

Frequently Asked Questions

How to address accuracy loss in aluminum enclosure machining caused by equipment aging?

How to ensure production efficiency and quality control for large-volume orders?

How to choose between spray coating and anodized oxidation for aluminum enclosure surface treatment?

How to balance innovative design and production feasibility for customized complex aluminum enclosures?

How to select aluminum alloy materials to ensure stability and durability for audio product enclosures?